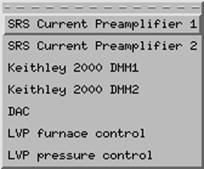

1.5 Other Electronics

This section

contains control records for the Stanford Research System’s preamplifiers (for

getting photo diode information), scaler, Keithley 2000 (for logging in analog signals such as

heating current, voltage, LVDT displacement information, oil pressure, etc.),

DAC (control signal for heating), and furnace and pressure control.

The electronics are used for various purposes.

·

SRS Current

Preamplifier 1 is not used by LVP.

·

SRS Current

preamplifier 2 is used for the magnifying the photo diode output

(beam intensity monitor),

·

Scaler for clock and photo diode readings,

·

Keithley 2000 DMM1 for logging DC signals such as LVDT,

pressure, thermocouple emf, etc. information.

·

Keithley 2000 DMM2 for logging AC signals such as voltage

and current of the AC power supply.

·

DAC for

sending control signal (0-10 VDC) to the power supply for heating. This is no

longer used directly as the control for heating.

·

LVP furnace control group (for PID

heating control), which can be found by clicking here.

·

LVP pressure control: for pressure ramping,

manual pressure increase and decrease

1.5.1. SRS current preamplifier 2 [SR570.adl]:

You can change the settings on the SRS preamps remotely by clicking these buttons. Especially, if the photo diode readings are around 640,000, it means it is saturated. You should (1) reduce the beam, and (2) change the sensitivity (e.g., from nA to microA).

1.5.2. Scaler [scaler_full.adl]:

1.5.3. Kiethley 2000 DMM1

First click on Keithely 2000 DMM1 will bring you to the following window:

Click on "More" and select "Multi-channel screen" will bring you to the following window. Remember to close the single-channel screen.

Make sure to click on the "INIT" bottom to activate the Keithley. Also make sure the "SCAN RATE" button is set at scan option (i.e., a rate is given, such as 0.1 second, 0.2 second, etc, NOT set at "EVENT" or "Passive"). Clicking on the "CALC" button next to any channel will open the calculation window (see below). You'll see that the number under "Result" gets updated every few seconds. DMM1 is used for all DC signals as shown in the above image.

1.5.4. DMM2 is for all AC signals

(volts and amps of the power supply). Note that the FUNCTION

button is set at AC. However, the Keithley has a

tendency of starting out with DC. So whenever this Keithley window is brought up fresh,

click the FUNCTION button to DC and then back to AC to be

sure that AC is really selected.

Each channel has a RAW and a CALC value. RAW is the raw input value, which can be manipulated to give a value more meaningful for the user. Click on CALC will open a calculation record. There are 12 variables with each CALC record, each with an Input link (which gives the input name of process variable) and a value (for that PV), which can be used for calculation in the Calc field. Constants can be entered under the Value column for calculation. In the example below, A is an input from thermocouple emf (Chan1_raw), B through F are fitting constants to convert emf to temperature. The expression in the Ch10_Calc field then calculates temperature.

1.5.5 DAC [DAC.adl]:

DAC controls the AC power supply by sending a DC voltage signal to the supply. The DC signal is from 0 to 10 V, corresponding to the output AC voltage from 0 to maximum (which is set up by choosing cable setups on the supply). This record is no longer used for temperature control. Click here to see furnace control information.

1.5.6 LVP Furnace Control

![]()

The LVP Furnace Control (found under Other

electronics on 13BMD.adl) directly controls the DAC (Digital to Analog

Converter) which controls the AC power supply control voltage. This control

voltage can be adjusted by either entering a value in the Control Voltage

field, or "tweaking" it with the two tweak buttons (see above). A

voltage limit can (and should) be set.

Note: you should always set a volt limit low enough to help reduce the risk

of power overshoot. However, if you

forget to raise the limit and find temperature is no longer increasing because

of this limit, DO NOT just raise volt limit, as the PID will try to shoot the

power up instantaneously based on the accumulated Proportional and Integrated

differences. When you hit the volt

limit, lower the temperature first so that you are no longer volt limited, change

the limit to a higher value and then increase the temperature.

The actual voltage produced by the power supply is a multiple of the control

voltage – 0-10 control volts corresponds to 0-Vmax of

the power supply (settings vary). The default ratio is 1:1 (see PID limits,

below)

Feedback control is available using the PID

(Proportional-Integral-Differential) system. This system can control on either

temperature or power. The Setpoint on the PID

feedback control window is set to the value you wish to control, whether power

or current. The Control PV adjusts the DAC (furnace power supply control

voltage).

The Readback PV monitors either the temperature

(13BMD:LVP_furnace_calcs.E NPP NMS) or power (13BMD:LVP_furnace_calcs.D NPP

NMS) (see furnace_calcs, below).

The limits and some of the calculations are in the PID limits window:

The AC power supply volts and current are in fields A and B, read from Kiethley #2. The resistance is calculated from these

values, and the power from the resistance. Field E is the ratio of the Control

Voltage to the power supply voltage, and is set here if other than 1:1. The

maximum valus for the power supply volts, current,

and power are fields F, G, and H, respectively and are also set here. Because

the limits are always in terms of control voltage, these fields are converted

to volts in fields I, J, and K. Finally, field P tells the PID to use the

minimum of I, J, and K, all divided by the control voltage:output voltage ratio, E.

Note: Field E is changed to match the

power supply settings, and fields F, G, and H may be user-adjusted.

The PID update window is used to transport control parameters.

Note that the upper left button (set as “Passive”) must be changed to a

certain update frequency (fro example 1 second) in order for the parameters to

be transported. When the state is set as

“Passive”, PID control will NOT be in control!!

The PID parameters (PID

feedback parameters) need to be adjusted when either changing the type of

furnace, or when changing from temperature to power control. Note that KD is

always zero or negative; the other terms are positive.

|

Controlled by |

KP |

KI |

KD |

|

Temperature |

0.001 – 0.005 |

0.5 – 1.0 |

0 |

|

Power |

.04 |

30 |

-15 |

The plot window allows the user to monitor how sell the controlled

parameter follows the setpoint. You must manually

adjust the range for both the setpoint (Control PV)

and the controlled value (Readback PV). These will be

in real units (°C or

Note: Current MEDM has a bug: after you input new display maximum and/or

display minimum, the plot will not re-scale when the “Replot”

button is pressed. There are two ways

to get around it. Either re-size the plot window by dragging it from one corner, or

kill the current plot window and re-open it.

The furnace calcs does just what its title

says. Notice that field D is the power, and E is the temperature. T is read

directly from Keithley #1 channel 10 (DMM1Ch10_calc.)

If a different type of thermocouple is used, this needs to be changed here to

the proper channel.

To summarize the limit situation:

Ultimately, the only thing that is controlled is the power supply control

voltage, which is the output of the DAC.

The DAC is the minimum of [(LVP furnace control control

voltage limit) and (PID update.P)]

PID update.P is the minimum of [(desired output)

and (PID limits.P)]

PID limits.P is the minimum of [(max volts),

(max amps´ resistance)

and sqrt(max

power´ resistance)], all

converted to control volt units by dividing by E.

So actually, this is the minimum of [(LVP furnace control control voltage limit), (max volts)/E, (max

amps´ resistance)/E, and sqrt(max

power´ resistance)/E].

The items in bold are all user controlled. If the power or temperature stops

increasing, all of these parameters must be checked and altered if necessary.

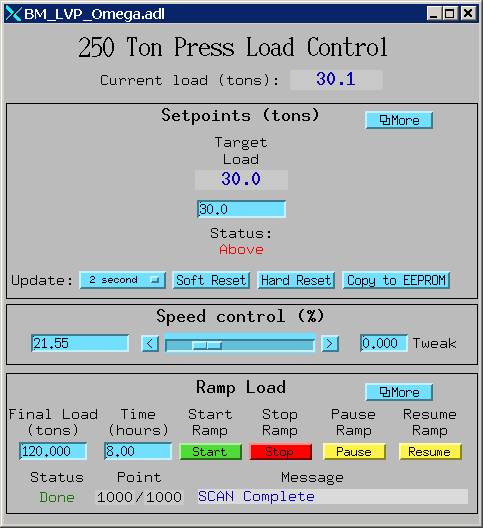

1.5.7. LVP Pressure

Control

This screen is divided in three parts. The top part, Setpoints is for setting the target load. Enter the target load in the blue window directly under “Target Load”. Note that “Update” must be in seconds or fraction of seconds (typical value: 2 – 5 sec). If it is set as “passive”, then setpoint will not be in effect.

The middle part of the screen is for speed control. The maximum speed (100%) is set manually on the pressure control box mounted directly on the VME crate. If the speed on the omega controller is set at 100 (RPM), then this will be the maximum speed the pressure control can automatically reach. One can choose a lower speed by changing the percentage to less than 100%.

The lower part of the screen is for ramp control. This will let one to define a ramp speed from the current load to the next target load (called “Final Load”) is a specified number of hours. This load range will be automatically divided into 1000 equal points, and MEDM will perform a scan operation between the initial and final load to increase the load according to the time intervals defined.

Note: as a good practice, always make sure that the lower guide block is in contact with the sample (i.e., sample is already under some pressure), in order to run the ramp control.